How To Repair A Sluggish Motor In A Drone

This guide will assistance yous understand the dynamics behind brushless drone motor used on quadcopters and how they influence flying characteristics. Nosotros'll swoop into types of motors, design variations, weight, total power and other factors affecting a quad motor functioning. So let's get started.

More than...

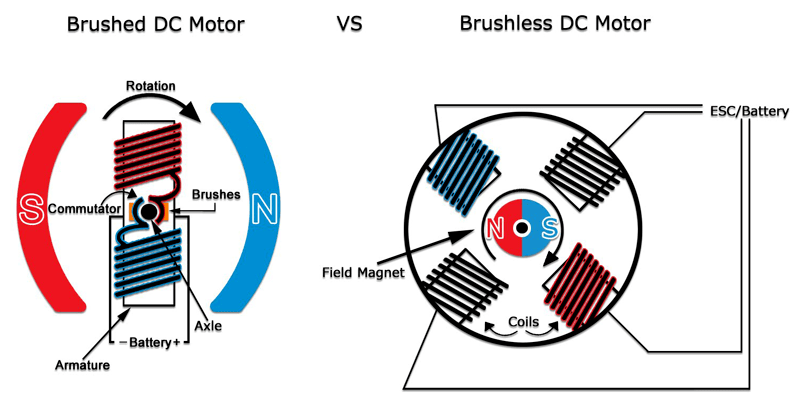

For beginners there are ii types of motors used in drones: brushed and brushless motors. They vary in the fashion they work. The brushless is way more powerful for their weight than brushed motors, and they last way longer. For bigger quads: no question, brushless is rex.

But for the micro and nano drones, information technology's fantastic to accept these cheap motors to crash with confidence.

The internal workings of a brushed and a brushless motor is the same; both are based on electromagnetism.

When the motor windings become energized (both the motors have coils), a temporary magnetic field is created that repels (and/or attracts) against the permanent magnets present within the motor.

This magnetic strength is creating the repulsive force in the coil that is used to spin/rotate the shaft.

Departure between brushed and brushless motors

Efficiency wise, brushless motors are typically 85-90% efficient whereas a brushed DC motor is 75-80%. Windings are present on the rotor for a brushed motor as compared to in a stator for a brushless motor

This difference in efficiency ways that more than of the total power used by the motor is existence turned into rotational strength and less power is being lost as heat.

Brushless motor lasts longer considering there are no brushes to wear out, while the brushed motor wears out apace. That'due south ane of the reasons brushed motors came out cheaper then brushless motors.

This guide is mostly oriented on brushless motors used in racing/freestyle fpv drone configurations.

The Basics of brushless motor

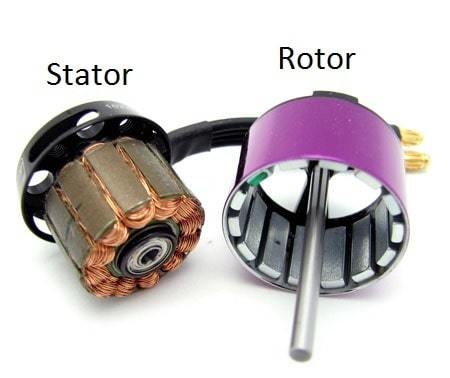

There are 2 major parts for a brushless motor chosen stator and a rotor. A picture is shown below for reference.

The stator is the stationary office of the motor(windings) and the rotor is the rotatory part of the motor(bell with magnets). Too there are a lot of other minor things such every bit bearings, coil, magnets, shafts etc.

A motor size is based on the stator size (bore and height).. For example if a motor is sized as 2207, it means that the stator is 22mm in width and has 07mm in stator top.

Also there is something chosen as a KV of a motor. What it means is that the speed at which the motor rotate for every volt applied to the motor, theoretically.

Thrust to Weight Ratio

Brushless motors come in all shapes and sizes. The general dominion of pollex is to aim for 2:i thrust to weight ratio. You aren't going to be able to do hard core racing with it. The college the improve plainly. The thrust to weight to ratio depends generally on the size of the quads themselves.

There are pre built quads such every bit from Diatone Crusader GT which has a thrust to weight ratio of 8:1. At that place are people who have achieved thirteen:1. But in that location are certain limitations for the motors, because they can just spin so fast and spinning them any faster makes them inefficient.

Fifty-fifty for a photography rig you should aim at least for 3 or 4:1 in case you make up one's mind to upgrade your setup in the future or add an Hard disk camera or a bigger battery for longer flying times or something, then you lot'll have some reserve power left to compensate.

For a drone racing beginner four or 5:1 thrust would exist the sugariness spot. If you're on a tight budget then build a fauna of a quad and limit the throttle limit on Betaflight or the transmitter.

Quad Motor Sizes - Taller and Wider stators

A motor is indicated by a set of iv numbers like 2207 or 2306 or whatever information technology may be. Information technology denotes the diameter and the height of the rotor in millimetre (mm). The bigger the motor gets the higher the thrust it generates.

- Taller stator = higher peak speed and terrible low speed handling

- Wider stator = lower height speed and amend treatment at lower speeds

The main cause is the increased magnetic field from the stators. The taller stators have larger magnets as compared to smaller and wider stators.

2207 vs 2306 motors

A good comparison would exist the typical 2207 vs 2306 motors. It is a hugely debated topic as to which is ameliorate and one tin't exist recommended over the other as both accept their advantages and disadvantages which volition exist covered in some other article.

Brushless Motor Size Nautical chart

The motor option is determined on how big you want to build your quad. Hence the proper noun Frame size = Motor size.

By determining the frame size we tin ascertain how large of a motor nosotros should utilise.

Frame size besides limits the prop size and each prop requires a unlike motor to spin it and generate the thrust efficiently.

Also the KV of a motor plays an important role in the pick of the motor. Equally mentioned before college KV draws more than current.

The table below shows the nominal frames and quadcopter motor numbers:

| Frame Size | Prop Size | Motor Size | KV |

|---|---|---|---|

| 150mm and smaller | 3" and smaller | 1105-1306 | 3000 and higher |

| 180mm | four" | 1806 | 2600-3000 |

| 210mm | 5" | 2204-2208/2306 | 2600-3000 |

| 250mm | 6" | 2205-2208/2306 | 2000-2300 |

| 300mm | 7" | 2208/2212 | 1600 |

Performance Factors

KV - Velocity Abiding

Theoreticly rc brushless motor KV rating represents the speed at which the motor rotates for every volt applied to the motor. For example if a motor is 2300kv with a 3S quadcopter bombardment motor applied to its ends then the motor will spin at 2600x12.60 =32,760 rpm (Revolutions per minute - number of turns in one minute), without propellers. The rpm decreases gradually because of air resistance.

Motor KV represents the speed at which the motor rotates for every volt practical to the motor.

Higher the KV means lower resistance and higher current depict and lower efficiencies. Lower KV ways higher resistance and lower electric current describe and considerably better efficiencies.

If yous're starting out somewhere effectually 2300-2400 KV would be desirable.

For example, if a motor is rated at 2300kv with a 3s bombardment voltage applied to information technology, then the motor volition spin at 2300x12.60 =28,980 rpm without the propellers, and it is the maximum rpm it can attain at no load.

The rpm sharply decreases when a propeller is mounted because of air resistance offered to the motor while spinning the propeller.

Torque

Moving on the next factor that comes into picture is the torque produced by the motor. Torque is the spinning force or the rotatory forcefulness that spins the propeller. It doesn't matter much if y'all're starting out.

Motor torque is afflicted by factors such as:

1. Stator size- bigger the stator higher the torque

2. Materials such as quality of magnets and copper windings in the rotor

3. Motor construction factors such as air gaps between stator and rotor.

Torque produced by the motor significantly affects the performance of the quad. It also determines how the quad is going to experience for the inputs. Higher the torque produced by the motor, the more responsive the quad will perform.

Torque besides governs how fast a quad change its direction mid-flying which volition greatly help to exercise tighter turns in a race. Relatively if a motor produces less torque and is fitted with heavier props, the motor can't spin the propeller and resulting in reduced efficiencies and likewise thrust. The current draw in an over propped motor will be significantly high.

The one major disadvantage of high torque motors are even though they feel more than snappy and responsive to the controls they have bad oscillation. Since motors with high torque are able to change their rpm more rapidly they really dilate the fault (oscillation).

Oscillation is hard to get rid of in Betaflight even with PID tuning,especially on the yaw axis of the quad.

Efficiency

The efficiency of a motor is calculated by dividing the thrust produced by the motor at 100% throttle past the power produced past the motor.

This is measured by grams per watt (thousand/due west). The higher this ratio, the more efficient the motor is essentially. We are non going to be flying 100% throttle the whole time; therefore it is important to consider the efficiency of the motor through the whole throttle range from 0% all the way up to 100% throttle.

Some motors may be efficient in the lower stop of the throttle curve and some motors may be more efficient in the college end of the throttle curve. Therefore it is of import to cull the right motor depending on the way of your flying.

Current Describe

Current drawn by the motor is important because it helps u.s. to determine the quadcopter esc size required for that detail motor.

For case, a 1104 motor draws 10A max at 100% throttle whereas some 2306 motors describe 40A max at 100% throttles. An esc must be selected appropriately for 20% more rating than the current drawn at 100% by the motor.

Ie; if a motor draws 30A max at 100% throttle, an esc rated for 36A constant current would be platonic.

There is also known as outburst rating of an esc. It'southward the maximum amps of current the esc tin handle for a short menstruation of time without damaging itself.

Temperature

Temperature or estrus in general is a killer of motors over time. If the motors are exposed to prolonged heating, the magnets in the rotor lose their magnetic field strength over fourth dimension. They demagnetize over time when exposed to constant heat and consequently resulting in a reduced lifespan of the motor.

The principal reasons for a motor to heat are over propping and using higher throttles for long periods of time. If you're a pro level drone racer, you will be running at higher throttles, but if y'all are just starting out and the motor heats and then the motor is over propped.

Only motor manufacturers compensate for this event by designing cooling fins to aid the motor to suck in air into the motor and cool itself equating to longer life spans, provided you don't crash and destroy the motor beforehand.

Other factors to consider

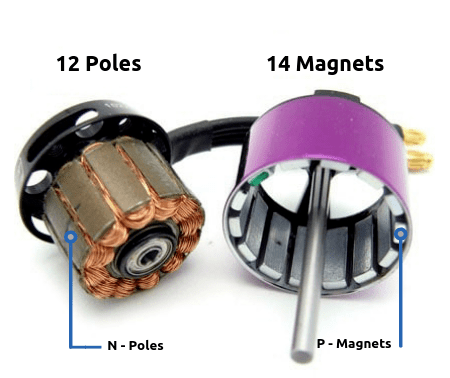

N and P numbers

A typical 22xx or 23xx motor volition have 12 poles and 14 magnets. This number will be denoted something similar 12P14N. As depicted in the diagram, the poles are present on the stator and the permanent magnets are establish on the rotor of a motor.

Single & Multi stranded wires

Single stranded wires as the proper name suggests is made of a unmarried wire of copper whereas multi stranded wires are fabricated of 3 smaller wires to replace the single thicker wire. Single stranded wires are thicker and handle estrus produced much ameliorate when used on high voltage builds.

Multi stranded wires intermission or melt easily at college operating temperatures. Typically multi stranded wires are more efficient considering they pack the wires much tighter and closer together, therefore giving stronger magnetic fields and resulting in more powerful motors.

Magnets

The magnets in a motor play an important role in deciding how powerful a motor is going to be.

Cheap motors will accept weaker magnets and produce less thrust every bit compared to an expensive motor which will have more powerful magnets.

Some higher-finish motors even take curved magnets which are contoured to the shape of the rotor.

Magnets used in brushless motors are graded based on the magnetic strength such as N52, N54 etc…, the higher the stronger the magnetic field produced past the magnets.

Motor windings

Another gene to consider is the quality of the windings of the motor. If the motor has loftier quality copper windings they're going to offering less resistance for the menstruum of currents and thus offering better efficiencies and longer flight times.

Motor Weight

The weight of a motor is governed by the size and materials of the motor. The bigger the motor the heavier information technology is. Keeping in mind the motors used on a 5" quad commonly weigh with wires effectually 30-twoscore grams. At that place are some very calorie-free motors such as the Emax RSII which weigh around 25 grams for a 2306 motor with a couple of grams for the wires.

At that place are some very heavy motors such every bit the cobra 2204 motors which counterbalance effectually 34 grams. As they say, every gram counts, specially with the motors. Why? Because the moment arm increases the heavier the motor gets. Simply put it takes a significantly big corporeality of force to plough a quad with increase in every gram.

But that doesn't mean lighter is better. Lighter motors are non as durable as the heavier ones considering they would be made of lighter materials to salve weight. Hence it all boils downward to what are you lot going to utilize the motor for.

Motor mounting patterns

The mounting patterns of a motor also matter considering it should be compatible with all the frames you lot choose to put the motor in. Most 5" quads these days use motor sizes from 2205 to 2407.

All the motors either have (16x16) mm or (16x19) mm mounting patterns. All the modern frames back up all those mounting patterns and this shouldn't exist much of a business organisation.

The higher up image shows a brushless motor in a quad. The screw holes will be nowadays on the stator of the motor. The above-shown motor or the stator has a 16x19 mm mounting blueprint and uses 4 m3 screws for securing the motor to the frame.

Features to look for in Motors

Motor Shaft

Newer motors nowadays use hollow shafts every bit opposed to a solid shaft in an attempt to reduce the weight of the motor. This has its positives and negatives.

Hollow shafts obviously reduce the weight of the motor but they're less durable during crashes.

Y'all can't replace shafts without replacing the whole rotor of the motor. For budget builders, hollow shafts are a bad thing just for those looking to save every gram hollow shafts are the way to go.

Air gap

Another thing for a better performing motor is the air gap between the stator and the rotor. The closer the rotor is to the stator (magnets to the windings) the more efficient it is in converting the electric current. The smaller the air gap the higher the thrust that motor produces every bit the stator slices through magnetic fields better.

Motor wires

The next thing that affects the functioning of a motor is the wire gauge of the motor. The motors either use 20 Awg or 18Awg (American wire judge). The Emax RS series claim that irresolute from a 22 judge to a 20 gauge wire increased the ability output by 5%. Merely this is no big deal when buying a motor and getting started in the hobby.

Retainer clips

The adjacent thing we are going to talk about is the retainer clips or retaining methods of the stator and rotor. There are mainly 3 types we use in our hobby.

- Eastward prune

- C clip

- Screw retainers

Each has their ain advantages and disadvantages.

For example: E clips are difficult to remove without breaking the clip itself. Screw retainers are hands removable and hence giving piece of cake access to the stator and rotor.

But screw retainers are prone to unscrewing and loosening over fourth dimension under the constant vibration of the motor and too run the risk of over tightening the shaft and making it harder for the motor to spin. 1 clip can't exist recommended over the other. It all the depends on what the motor is going to be used for and its applications.

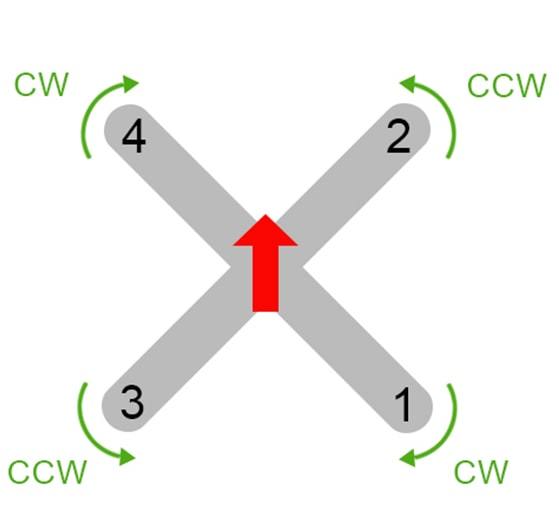

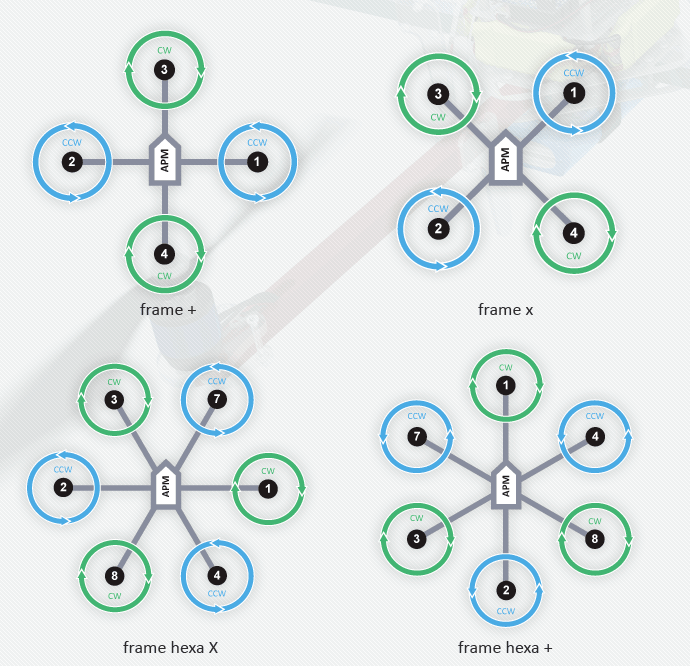

CW CCW motors

There are 2 types of motors- clockwise (CW) and counter clockwise (CCW) rotation motors. They vary only by the direction by which they rotate with the rest of the design parameters of the motor being the aforementioned. The below diagram shows a motor orientation for a quad, hex and octa drone. We can conclude that opposite side motors spin in the same direction. It is the aforementioned in hex and octa drones.

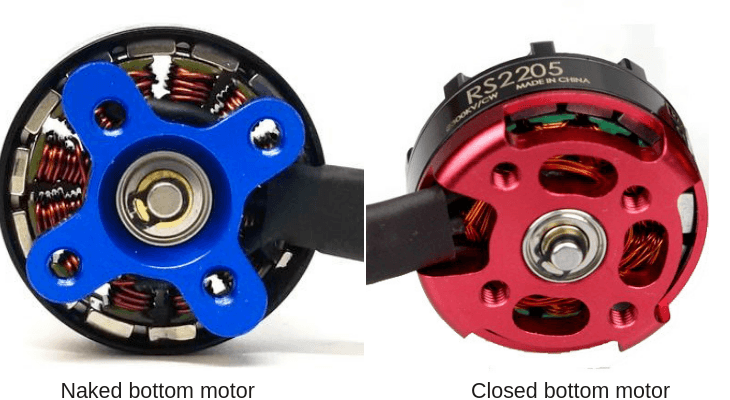

Naked bottom OR Closed bottom motors

The latest trend in quad motors are naked bottom motors. They save a lot of weight (2g in general), it may not seem much but that'south a lot in terms of drone racing. Information technology may exist the departure between winning a race or losing one.

Those are the pros of the naked lesser motors, there are also a few cons for these type of motors.

Firstly during a crash small stones and debris may get inside the bell and damaging the magnets and coils. Fifty-fifty pro racers crash often and so it's a practiced choice for beginner's to purchase a closed lesser motors when starting out in the hobby because they're decumbent to crash more. The below photographs depict a naked and closed bottom motors.

Conclusion

This commodity has tried to encompass nearly of the bones aspects of a brushless motor for a quad. It will be modified in the futurity with some modifications to it as and when information technology is deemed necessary. There are so many options out there to choose from and we thought information technology should be covered in some other commodity. We promise this article helped you in some manner to assistance yous gain some basic noesis getting into FPV. Cheers for reading if y'all stayed all the way to the end.

Source: https://dronenodes.com/drone-motors-brushless-guide/

Posted by: hernandezconsis.blogspot.com

0 Response to "How To Repair A Sluggish Motor In A Drone"

Post a Comment